DIY 48V LiFePO4 Battery Pack

At first, we need choose 16 pieces 3.2V LiFePO4 (Lithium Iron Phosphate) battery,confirm that this voltage matches the requirements of your application,we may choose 100ah,200ah or 300ah, and we will full charge and discharge them by equipment. and select the same specifiactions battery

Testing the capacity of a LiFePO4 (Lithium Iron Phosphate) battery involves measuring how much energy it can store and deliver under certain conditions. Here's a general procedure for testing the capacity of a LiFePO4 battery:

Fully Charge the Battery: Charge the LiFePO4 battery to its maximum capacity using an appropriate charger designed for LiFePO4 batteries. Ensure that the battery reaches its full charge and that the charger terminates the charging process correctly.

Discharge the Battery: Connect a known load to the fully charged LiFePO4 battery. The load should draw a consistent current that allows for a controlled discharge. Monitor the voltage of the battery during the discharge process to ensure it stays within safe operating limits.

Measure the Discharge Time: Allow the battery to discharge at a constant rate until its voltage reaches a predetermined cutoff voltage, typically around 2.5-3.0 volts per cell for LiFePO4 batteries. Measure the total time it takes for the battery to discharge from full capacity to the cutoff voltage.

Calculate Capacity: Calculate the capacity of the battery using the following formula:

Capacity (Ah) = Discharge Current (A) * Discharge Time (hours)

Ensure that the discharge current is consistent throughout the test and that the discharge time is measured accurately.

Repeat and Average: To ensure accuracy, it's a good idea to repeat the test multiple times and average the results to account for any variations in the testing conditions.

Evaluate Results: Compare the measured capacity with the manufacturer's specified capacity or the expected capacity based on the battery's specifications. The measured capacity should ideally be close to the rated capacity, although some variation is normal.

Consider Factors: Keep in mind that the actual capacity of the battery may vary depending on factors such as temperature, discharge rate, and the age/condition of the battery. And we will match the same same battery , and put them together in the same pack to assemble.

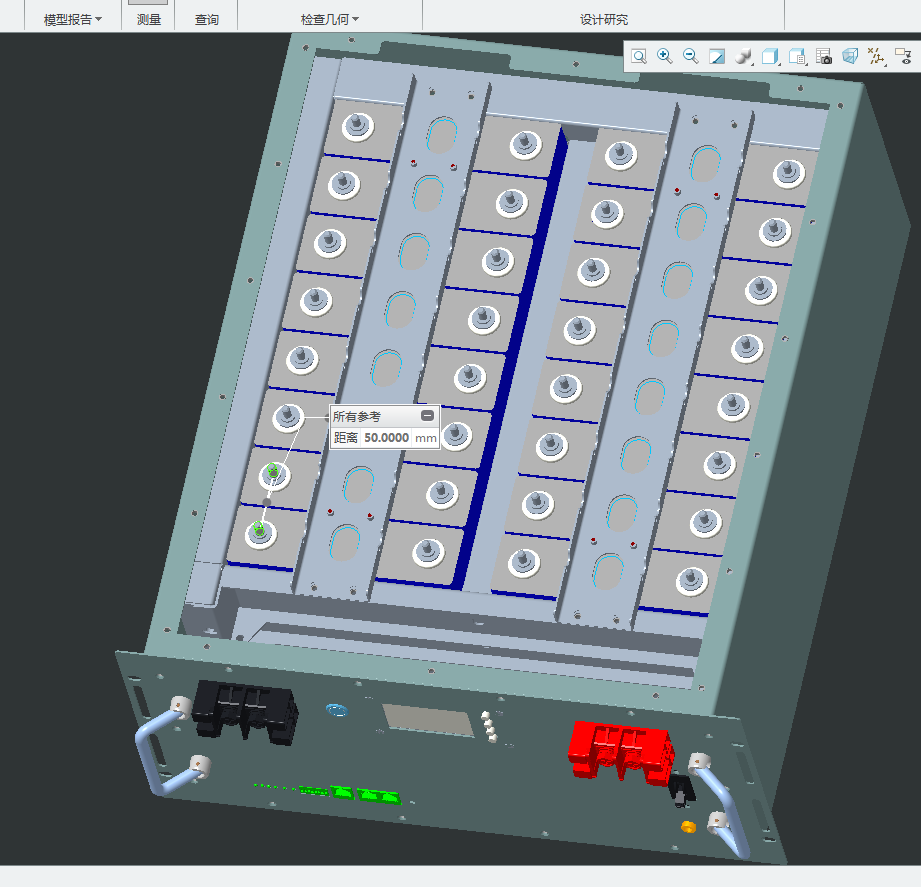

Battery prepared and Our engineer design the metal box according to the dimensions of the battery and each parts.

This metal box provide a protective enclosure for sensitive electronics or power equipment that require a stable 48-volt power supply. These metal boxes are typically designed to meet certain specifications such as size, material, and environmental protection ratings to ensure the safety and functionality of the equipment they house. They may also include features like mounting brackets, ventilation, and cable entry points for easy installation and maintenance.

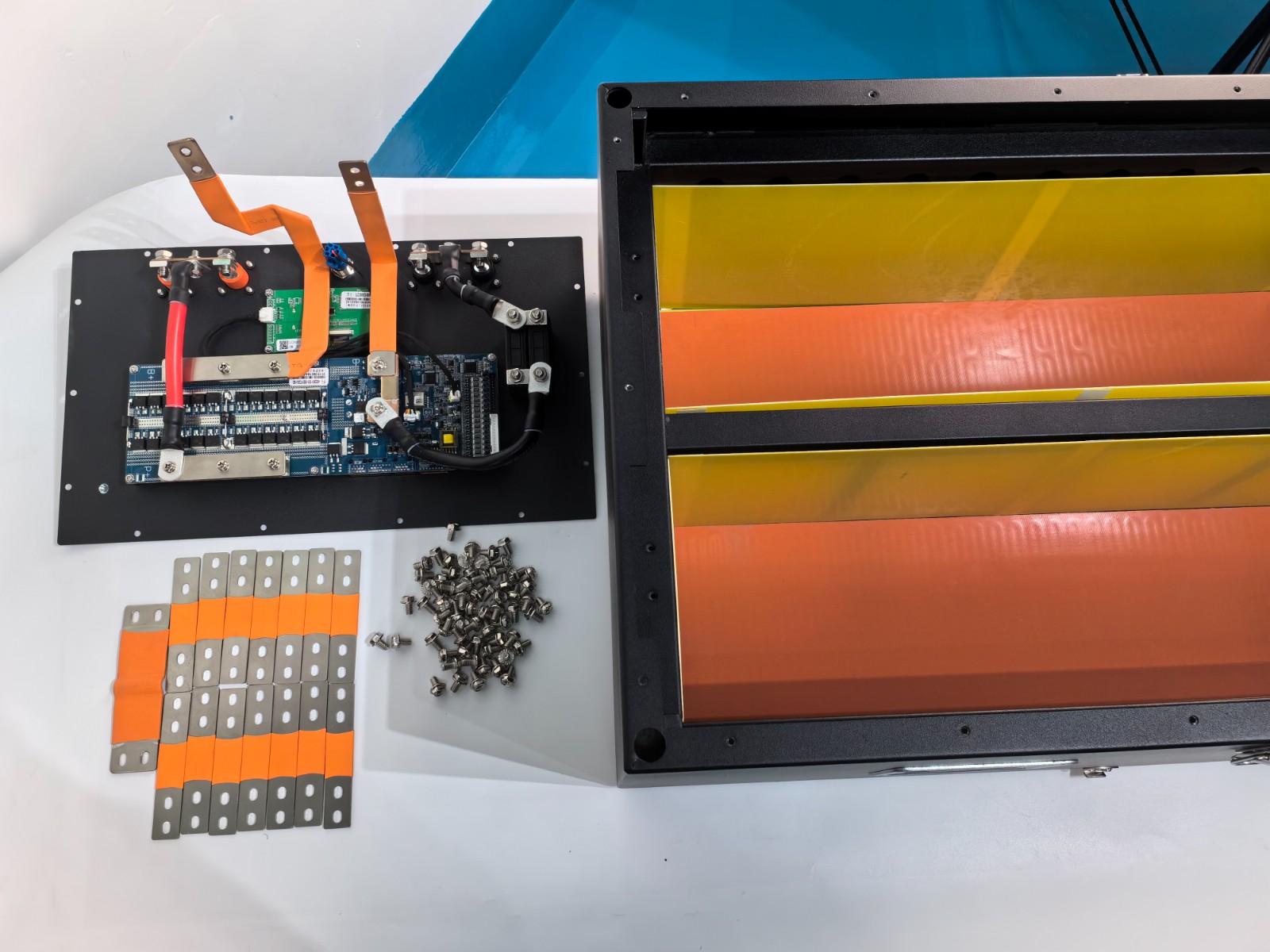

We will install the other accessories included the BMS, switch, cable, temperature sensor,etc.

Materials Needed:

LiFePO4 battery cells (make sure they are rated for 48V operation)

Battery management system (BMS) suitable for LiFePO4 chemistry and 48V operation

Spot welder or appropriate welding equipment

Nickel strips or busbars for interconnecting cells

Insulating materials (such as fish paper or Kapton tape)

Enclosure or battery box

Wiring and connectors

Tools (such as wrenches, screwdrivers, wire cutters, etc.)

Steps:

Prepare the Battery Cells:

Ensure that all LiFePO4 cells are of the same type, capacity, and voltage rating.

Check each cell for any physical damage or defects.

Arrange the cells in series configuration to achieve the desired voltage (48V in this case). This typically means connecting cells positive terminal to negative terminal in a chain.

Spot Welding:

Use a spot welder or appropriate welding equipment to connect the cells in series with nickel strips or busbars. Take care to weld them securely, ensuring good electrical conductivity and mechanical strength.

Install the BMS:

Mount the battery management system (BMS) to the battery pack. The BMS is crucial for monitoring individual cell voltages, balancing cells during charging, and protecting the battery from overcharge, over-discharge, and overcurrent conditions.

Connect the BMS:

Connect the BMS wiring to each cell in the pack according to the manufacturer's instructions. This typically involves connecting balance leads to each cell and the main positive and negative terminals of the pack.

Insulate and Secure:

Insulate the exposed metal parts of the battery pack with insulating materials such as fish paper or Kapton tape to prevent short circuits.

Securely mount the battery pack inside the enclosure or battery box using appropriate brackets or mounting hardware.

Connectors and Wiring:

Install wiring and connectors for connecting the battery pack to the load or device it will power. Use appropriately sized wires and connectors capable of handling the maximum current draw of the system.

Testing:

Before putting the battery pack into service, perform thorough testing to ensure proper functionality and safety.

Test the voltage of each cell using the BMS to verify that they are balanced.

Check for any signs of overheating or abnormal behavior during charging and discharging.

Installation:

Once testing is complete and the battery pack is confirmed to be working properly, install it in its intended application following any specific installation instructions or guidelines.

Maintenance:

Regularly monitor the battery pack's performance and condition, and follow any recommended maintenance procedures provided by the manufacturer.

By following these steps carefully, you can assemble a 48V LiFePO4 battery pack that is safe, reliable, and suitable for use in various applications. Always prioritize safety and follow best practices when working with lithium batteries.

The Monitoring system we installed in computer will tell us all the data when working.